How Mi Water Purifiers Are Produced at VIOMI?

- 22.12.2017

- 3398

- Joney Tour

- Add new comment

Every

The quality requirements at the factory are very strict: the temperature and humidity are always kept on the same necessary level. Every day the room is treated with UV rays. This is very important, because cleanness is directly related to health.

The main details like the electrical board will be tested under the voltage.

Besides the necessary production conditions, the company also pays attention to such the materials and direct management of the process at all the stages of production.

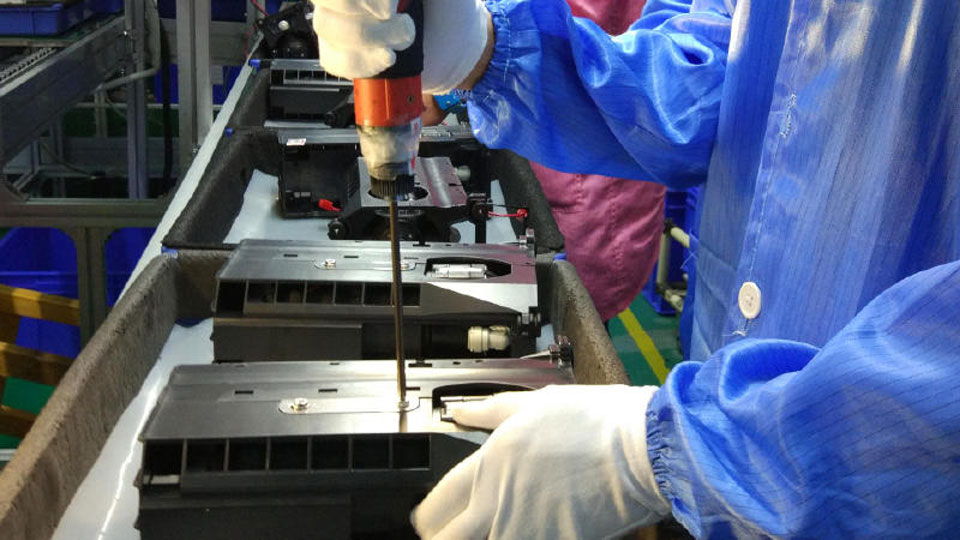

The first stage begins with the quality check of all the details. Every detail is an important mechanism of the system, so the malfunction of one part can disable the entire device. For example, this board provides the power and functional control of the purifier.

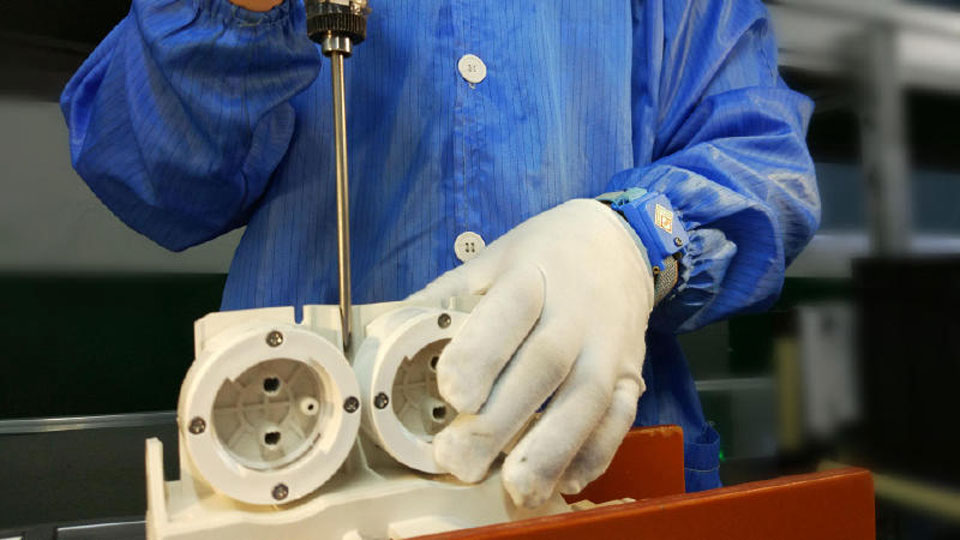

And this is a 400 gallon reverse osmosis pump. Before heading to the assembly line, it will be checked for leaks and its electrical characteristics will be tested.

The output pressure of the pump is 0.8MPa, that is equal to 8kg of water pressure.

The second stage is cleaning and disinfection of all the components. The next step is the assembly with testing. Two hours of intensive work and multiple tests which will help to identify the shortcomings.

After that follow the final assembly and re-testing of the device’s operability. If the Mi Water Purifier works well, it will be placed in the vacuum package.

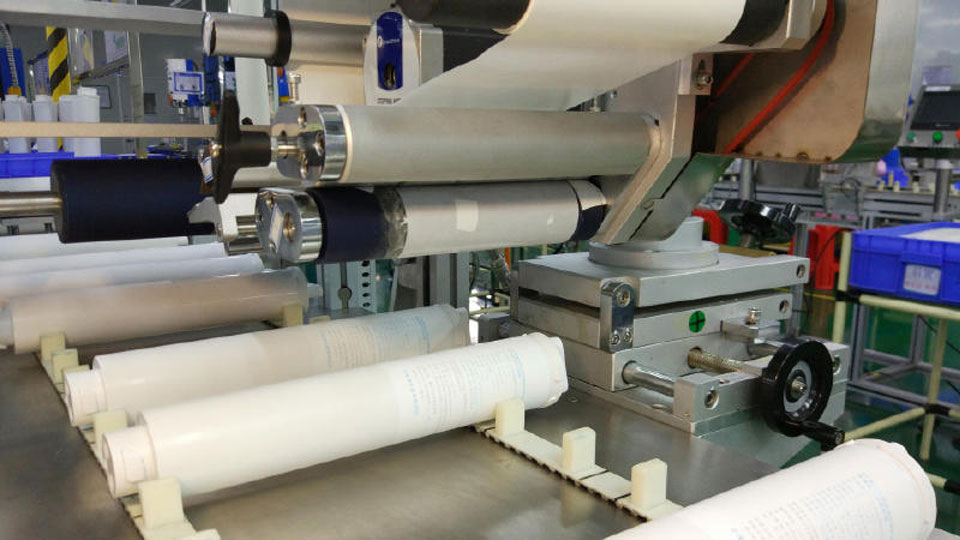

A separate stage is the manufacture of filters. Viomi purifiers offer a four-stage water purification system, which will help get rid of the impurities (heavy metals, bacteria, and rust) effectively. For its production only the best quality components are used. One of them is the activated charcoal made from Japanese peat.

The filtration material will be put into the filter and after that hermetically weld with the rotary welding seal.

All the parts of the water purifier that contact with water must be clean and disinfected.

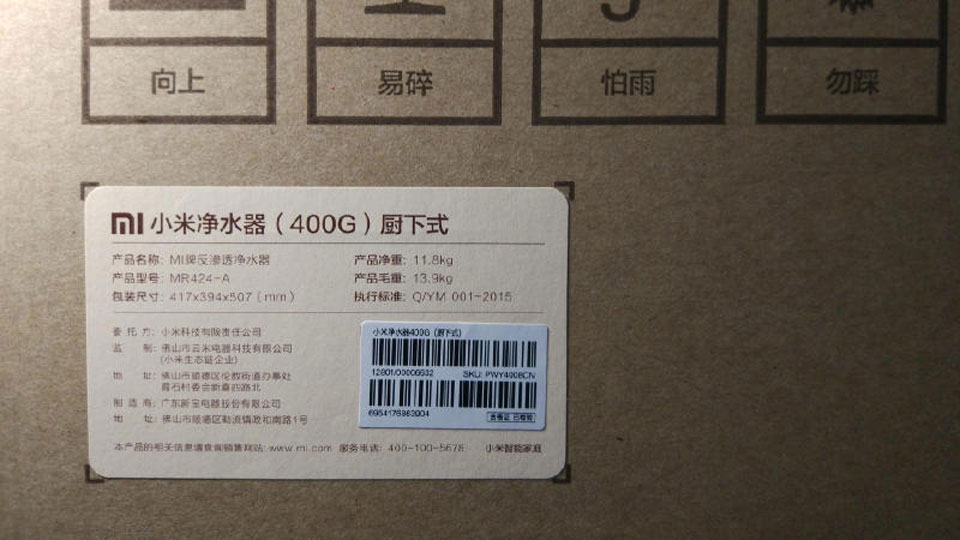

The eighth stage is the delivery directly to the user. Each box with a water purifier is labeled. For greater transport safety, the containers are wrapped in the film.

That’s exactly how your favorite water purifiers are made. After that, they are travelling a long way to different parts of the world to provide clean water to every home.